Tool Design and Manufacture

KJ Precision Engineering has 50 years of experience in creating Tooling for new products and has therefore turned countless ideas into reality.

The design phase begins with accurately understanding your idea and ultimately what you want to achieve. Our designer, Peter Thompson has a way of extracting all the relevant information that will create a feeling of confidence in your product design. Then the work of drawing and designing begins. Once you are completely comfortable, a tool will be made.

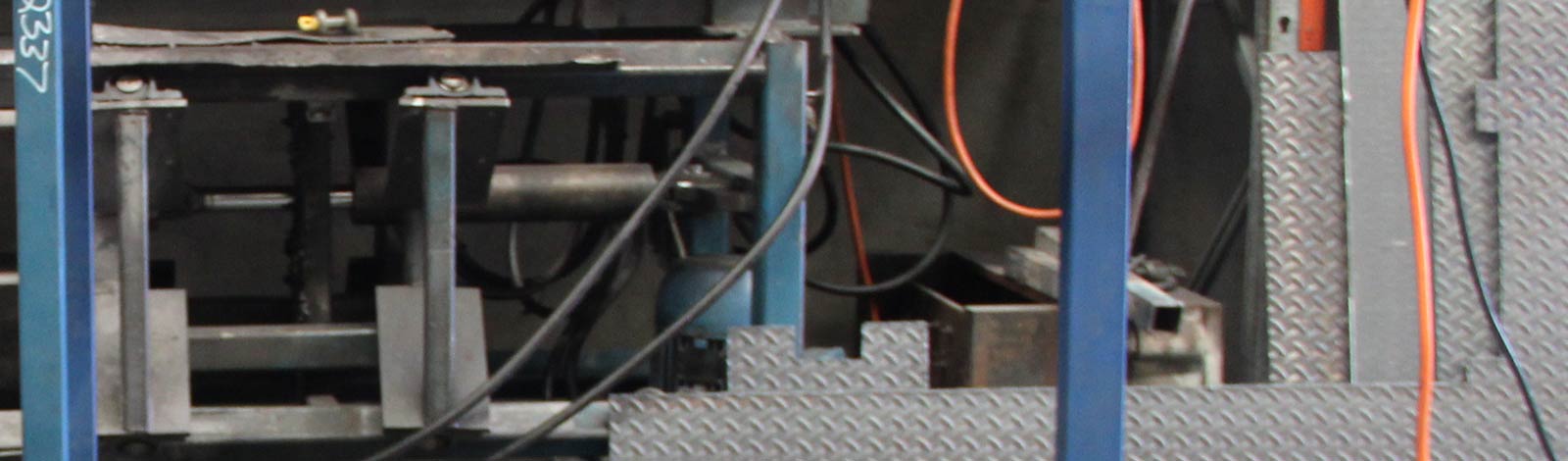

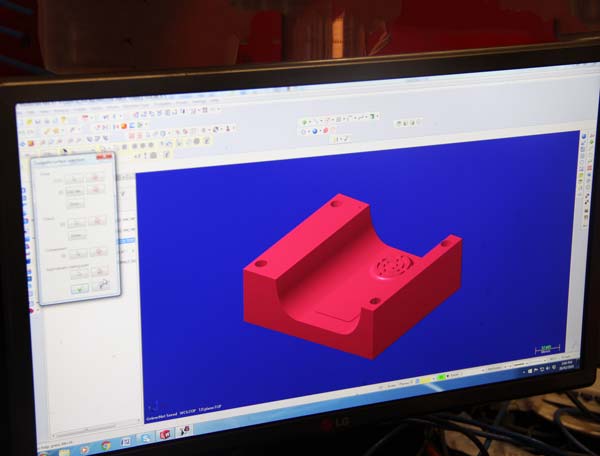

All tooling is manufactured on site with the standard material used being 4140 Tool steel. This mould is created by using a highly technical computer programing to first draw a 3D model. This program is then fed into the CNC machine and monitored continuously until the tooling is created. One of the greatest and most important challenges is to design the tool with the ability to accept molten aluminium in a way which gives the highest quality finished product achievable. Over half a century of experience in this style of tool design is a tremendous asset in gaining an efficient and accurate end result. This flows on to quality and service.

Some of our designs include marina cleats, café furniture, outdoor seating, outdoor telephones and many component products.